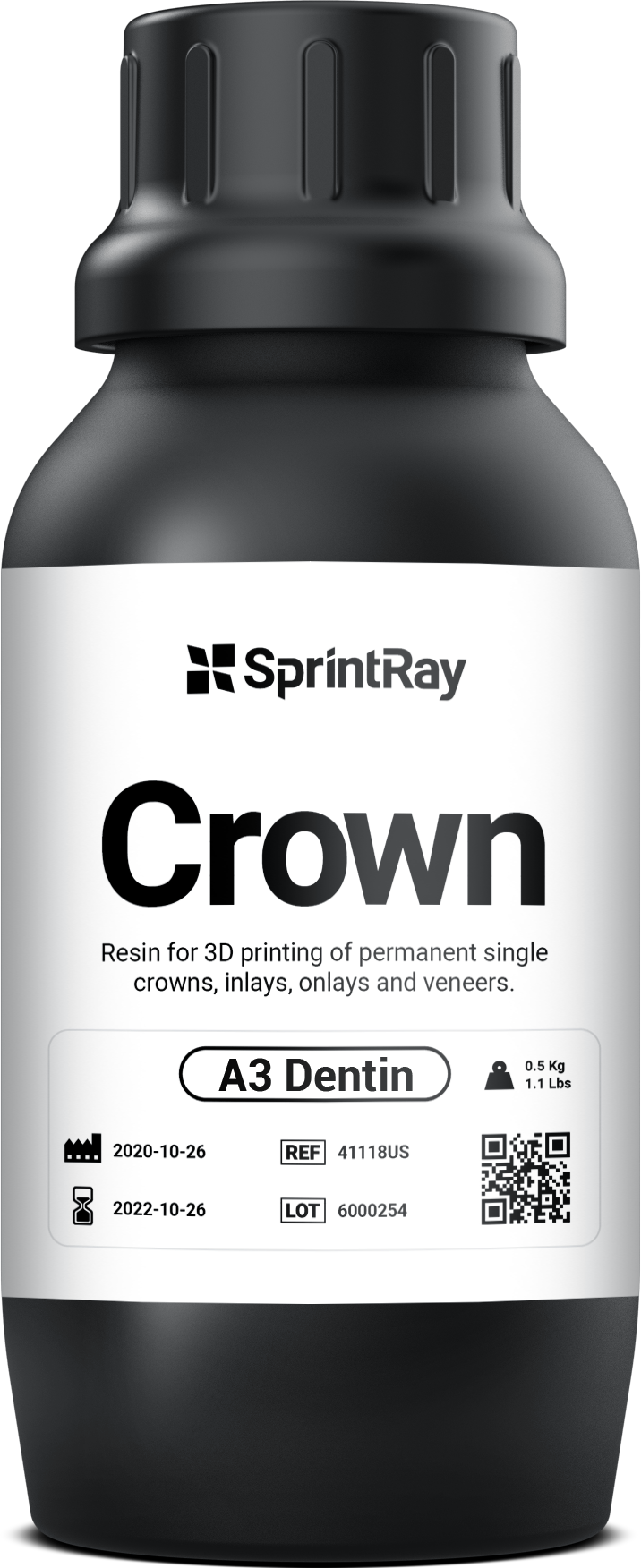

Dental crown restoration is a common procedure in dentistry for damaged or weakened teeth. Traditionally, this process has required multiple visits to the dentist and the involvement of an external dental laboratory for crown manufacturing. However, advancements in digital dentistry have introduced automated resin printing systems with a high range of strengths, containing ceramic particles in their composition, such as SprintRay resins (Fig. 1), which provide mechanical resistance comparable to the natural wear of teeth. In the future, we can expect even higher resistance with resins containing up to 50% ceramic particles in Europe.

Fig. 1

In this article, we explore the SprintRay Crown Kit (Figs. 2 & 3), a revolutionary tool that enables the fabrication of dental crowns in less than 15 minutes using intra-oral scanning technology and artificial intelligence-powered (AI-powered) printing.

This system gives both dentists experienced in and dentists new to digital technology a fast and precise alternative for tooth restoration with crowns, reducing treatment time and improving the patient experience. It not only allows dentists without digital expertise to carry out the printing process, but also provides clear instructions for auxiliary staff, giving logical and standardised steps.

What are the steps to be followed in the all-in-one printing protocol?

The first step involves intra-oral scanning of the prepared tooth using a high-precision intra-oral scanner. This digital scan is then transferred to dental design software for crown planning (Fig. 4). Such software allows the dentist to customise the shape, size and other aesthetic details of the crown, ensuring a precise fit and natural appearance. Once the design has been completed, it is sent for printing to the designated printing platform, which seamlessly receives the file and utilises AI algorithms to position the design optimally, suggesting the best orientation for optimal results.

What design systems can be used?

Several systems are available, including AI SprintRay, Medit app, CAD/CAM Designer (freelance) and Clinux. AI SprintRay is an AI-based design system provided by SprintRay Cloud Design (Fig. 5). This system is available 24/7 and can interpret and generate a crown design based on user-selected parameters recommended by the intelligent system. Within 5 minutes, the design will be ready for direct printing with a high level of precision. It also provides an additional model for verifying the peripheral fit and sealing of the scanned abutment (Fig. 6). Both images are sent to the computer through the cloud printing app, allowing the dentist to download them as files or print them simultaneously. The additional model serves as support for polishing the crown during post-processing, providing convenience in handling the crown without touching it with fingers. (Fig. 7).

The Medit app is a crown fabrication system within the Medit Link app (Fig. 8). It allows for personalised and free design based on a preoperative case or a new crown, utilising a modifiable tooth library and simple brushing tools to add or remove material as needed. It is also adjustable for contact points and antagonist relationships.

The CAD/CAM Designer (freelance) system provides an STL file of the crown, which can be imported into the SprintRay printing software to obtain the crown within 15 minutes and complete the necessary post-processing for immediate delivery (Fig. 9). The design file can also be visualised on a mobile phone using the exocad viewer app before approving the design. Once approved, the design can be sent through a download platform like Google Drive or via email to upload it to the printer from the designated folder.

Clinux is an intuitive cloud-based CAD software provided by CAD-Ray. There is direct access to the design program from the scanning program, enabling easy designing and subsequent one-step printing (Figs. 10–12). This intuitive design system is user-friendly and suitable for any dentist or trained auxiliary staff member who understands the basic concepts of proximal contact and occlusion adjustment.

What do I do once the crown has been designed or received?

Once the design has been completed, the data is sent to a specific printing unit. To minimise printing time, the SprintRay Pro 55S and its high-speed SprintRay Crown Kit system are used. If the AI option from SprintRay is chosen, the dentist receives files containing the design and the additional model for verifying the fit once printed. After the manufacturing process has been completed, the crown is tested on the prepared tooth, and any necessary adjustments are made before definitive cementation. Glazing and characterisation can be done using special stains, such as VITA stains, after removing any residual resin and polishing and buffing the crown with special brushes (Fig. 13).

Discussion

The SprintRay Crown Kit offers significant benefits for dentists and digital laboratories. Most importantly, it drastically reduces treatment time, allowing the fabrication of printed crowns in less than 15 minutes. Furthermore, the precision of automated printing ensures an excellent fit of the crown, minimising the need for subsequent adjustments and increasing patient satisfaction This not only improves the efficiency of the dental office but also provides a more convenient solution for patients by avoiding multiple visits and reducing the overall treatment time, differentiating the practice from the competition by offering a service that can be completed in a single visit.

In double-blind studies, it has been observed that the flexural coefficient of SprintRay Ceramic Crown is similar to that of natural teeth (over 100 MPa), and the average compression resistance of restorations made from this material is approximately 150 MPa. However, these values may vary depending on the location and individual structure of the restoration. Natural teeth can also withstand significant flexural forces owing to their internal structure, which includes hard enamel in the outer layer and underlying dentine.

Resin crowns can exhibit similar characteristics, depending on factors such as the design and thickness of the printed resin, centric occlusion, design of the preparation (avoiding sharp edges and ensuring the distribution of occlusal forces; Fig. 14) and protocol-based printing sequence and complete post-processing according to the manufacturer’s instructions. Additionally, the resistance of both the resin and natural teeth can be influenced by the quality of the adhesive used, the type of dental preparation performed and other specific clinical factors.

Editorial note:

This article was published in 3D printing—international magazine of dental printing technology vol. 3, issue 2/2023.

:sharpen(level=0):output(format=jpeg)/up/dt/2024/07/Asiga-showcases-human-centred-design-at-DDS.Berlin1.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2024/06/At-SHINING-3D-our-aim-is-to-enhance-the-lives-of-dental-professionals-through-cutting-edge-technology.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2024/06/Researchers-develop-novel-approach-to-dental-restoration-using-3D-printing.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2024/04/3D-printing-inlays-onlays-and-overlays-with-SprintRay-A-revolutionary-approach-to-dental-restorations_1.jpeg)

:sharpen(level=0):output(format=jpeg)/up/dt/2024/05/UnionTech-empowers-dentistry-with-the-latest-dental-3D-printing-solutions.jpg)

:sharpen(level=0):output(format=png)/up/dt/2022/01/Sprintray_Logo_2506x700.png)

:sharpen(level=0):output(format=jpeg)/up/dt/2024/03/Printing-crowns-in-less-time-than-it-takes-to-brew-a-cup-of-coffee-Header.jpg)

:sharpen(level=0):output(format=png)/up/dt/2024/03/Dr-Fernando-German-300x300.png)

:sharpen(level=0):output(format=bmp)/up/dt/2024/03/Printing-crowns-in-less-time-than-it-takes-to-brew-a-cup-of-coffee_fig-2.bmp)

:sharpen(level=0):output(format=jpeg)/up/dt/2024/03/Printing-crowns-in-less-time-than-it-takes-to-brew-a-cup-of-coffee_fig-3.jpg)

:sharpen(level=0):output(format=png)/up/dt/2024/03/Printing-crowns-in-less-time-than-it-takes-to-brew-a-cup-of-coffee_fig-4.png)

:sharpen(level=0):output(format=bmp)/up/dt/2024/03/Printing-crowns-in-less-time-than-it-takes-to-brew-a-cup-of-coffee_fig-5.bmp)

:sharpen(level=0):output(format=bmp)/up/dt/2024/03/Printing-crowns-in-less-time-than-it-takes-to-brew-a-cup-of-coffee_fig-6.bmp)

:sharpen(level=0):output(format=jpeg)/up/dt/2024/03/Printing-crowns-in-less-time-than-it-takes-to-brew-a-cup-of-coffee_fig-7.jpg)

:sharpen(level=0):output(format=bmp)/up/dt/2024/03/Printing-crowns-in-less-time-than-it-takes-to-brew-a-cup-of-coffee_fig-8.bmp)

:sharpen(level=0):output(format=bmp)/up/dt/2024/03/Printing-crowns-in-less-time-than-it-takes-to-brew-a-cup-of-coffee_fig-9-1.bmp)

:sharpen(level=0):output(format=bmp)/up/dt/2024/03/Printing-crowns-in-less-time-than-it-takes-to-brew-a-cup-of-coffee_fig-10.bmp)

:sharpen(level=0):output(format=bmp)/up/dt/2024/03/Printing-crowns-in-less-time-than-it-takes-to-brew-a-cup-of-coffee_fig-11.bmp)

:sharpen(level=0):output(format=bmp)/up/dt/2024/03/Printing-crowns-in-less-time-than-it-takes-to-brew-a-cup-of-coffee_fig-12.bmp)

:sharpen(level=0):output(format=jpeg)/up/dt/2024/03/Printing-crowns-in-less-time-than-it-takes-to-brew-a-cup-of-coffee_fig-13.jpg)

:sharpen(level=0):output(format=bmp)/up/dt/2024/03/Printing-crowns-in-less-time-than-it-takes-to-brew-a-cup-of-coffee_fig-14.bmp)

:sharpen(level=0):output(format=jpeg)/up/dt/2021/09/Interview-3D-printing-in-dentistry-is-much-more-than-just-a-new-technology_2.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2021/09/3D-printing-overview_780x439.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2021/09/SprintRay-booth-IDS_4_CEO-Patrick-Thurm_780-x-439.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2022/05/SprintRay-innovations-enable-faster-3D-printing-workflows.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2021/11/shutterstock_1310240776.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2022/01/SprintRays-NightGuard-Flex.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2023/03/SprintRay-presents-3D-printing-solution-at-IDS-2023_2.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2021/09/SprintRay-Protect-a-Smile-Occlusal-Guard-1.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2021/10/SprintRay-announces-multi-year-partnership-with-Usain-Bolt.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2024/04/3D-printing-inlays-onlays-and-overlays-with-SprintRay-A-revolutionary-approach-to-dental-restorations_1.jpeg)

:sharpen(level=0):output(format=jpeg)/up/dt/2024/04/SprintRay-introduces-revolutionary-3D-printer-Midas-enabling-use-of-highly-viscose-resins-1.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2024/01/SprintRay-ecosystem.jpg)

International / International

International / International

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

USA / USA

USA / USA

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Japan / 日本

Japan / 日本

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Middle East / Middle East

Middle East / Middle East

To post a reply please login or register